The Greenhouse Effect

New technology brings affordable nutrients to the table

By Darius Jones

Dotting the landscape in almost any countryside setting, the artificial environments created by greenhouses are the living quarters for an increasing number of the foods we consume. While this affords us the luxury of tomatoes and kiwis during the frosty winter months, severe flaws in technology cause temperature fluctuations and an over-reliance on chemical fertilizers that lower the efficiency of production as well as adversely affecting the conditions in which the produce is grown.

A 50-year study by the University of London has documented a significant drop in the amount of vitamins and minerals contained in the foods we eat. Extensive medical research has been done analyzing the detriments to health caused by mineral deficiency, both in developing countries and closer to home. Moreover, modern lifestyle-related illnesses such as lung disease, cardiovascular illnesses and cancer have been tied to a lack of proper nutrients by researchers worldwide. Yet the need for standardized produce year round keeps agriculturalists closely tied to the use of chemical fertilizer and pesticides.

Commonly used in greenhouse cultivation, these chemicals deplete the soil of vital minerals, leaving already suffocating plants with fewer resources, and this often results in a fruit that may look appetizing, but is bland and empty of the health-giving benefits its natural cousins provide. We are left with an affordable and accessible but inferior product. Unfortunately, the alternative organic fruits and vegetables are infamously difficult to produce, and although they tend to sell at a higher premium, the amount of labor that is necessary during the growing process makes many farmers hesitant to lay aside their pesticides and chemical fertilizers. Although organic farming has taken off elsewhere, in Japan organic vegetables currently only account for 0.16% of all produce grown by domestic farmers.

Takeo Sugiura, Radiant Systems Founder -- Photography by Hiromi Iguchi

Takeo Sugiura, Radiant Systems Founder -- Photography by Hiromi Iguchi

Chemicals are used in combination with overhead heating systems to create the artificial environment crops thrive in. The vast majority of farmers use hot air heaters suspended above plants, a system which, according to estimates by Ohio State University, only provide 60% heating efficiency. However, research has shown that the temperature of plant roots (known as the root zone) is the most important factor in producing a healthy and flavorsome product. Different crops have ideal root zone temperatures, and if this is achieved, air temperatures can be lowered while still maintaining the optimum environment for plant growth. This lower air temperature translates into less energy used to heat the greenhouse; the United States Department of Agriculture and various university studies have reported energy reductions between 30 and 50%. Energy reductions result in direct savings for farmers, a huge bonus in a financially strapped industry.

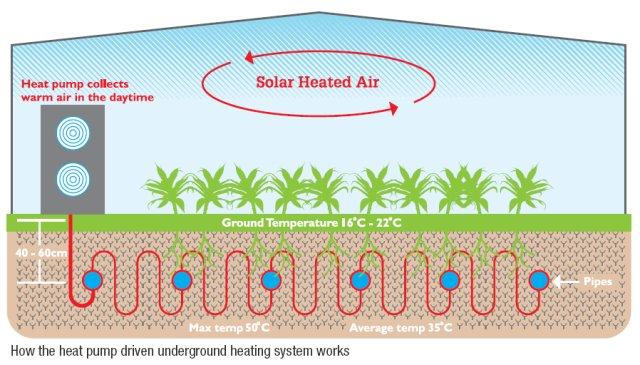

The current situation is far from ideal. 60 of the total 530,000 green houses in Japan have no heating systems, and the 40% that do cannot maintain a sufficient root zone temperature. However, an alternative system commonly used in the United States has been proven to have almost 90% efficiency in creating and maintaining effective temperatures both in the root zone and in the house itself. Utilizing a web of pipes buried below crops through which a hot liquid is circulated, ground heating systems take advantage of the earth’s natural insulating ability and use it to heat a green house 24 hours a day.

Creating fertile ground

Although the technology is available Japanese agriculturalists have been hesitant to change, and the industry continues to survive on traditional heating methods or no heating at all. Hoping to revolutionize a struggling industry, Tokyo-based Radiant Corporation has been working to provide farmers with an effective alternative, the Radiant Underground Heating System. The company, which also installs floor heating and other heating and cooling systems, has received backing from several prefectural governments, and research is currently being done by Miyazaki Prefecture to explore the full benefits of the technology. Founder Takeo Sugiura originally praised the system for its role in energy reduction, and after testing it himself in Nagano Prefecture, presented the idea to the Hokkaido government. “I wanted to try the system out in the coldest place in the country,” says Sugiura, and with temperatures falling below -20°C he and a willing farmer put the Radiant underground heating system to the test. A year later the data came through, and the system passed with flying colors.

The mechanics of the Radiant System are simple. A boiler pump works to heat water to 50°C and circulates it through plastic pipes buried between 40 and 60cm below ground. Heat is conducted from the pipes into the soil, which absorbs and holds the heat below the crops. During the cooler months this heat is supplemented with a conventional heating system. Even so, the Radiant System is still cost efficient because the energy used by the heater is only a fraction of the normal amount. Sensors in the soil allow farmers to adjust the system accordingly for each fruit or vegetable’s ideal root zone temperature.

Although well known for its energy- saving qualities, Sugiura has developed a second use for the system, one which addresses the problem of the laborious and flawed task of disinfecting greenhouse soil. In order to kill off harmful microbes and pests greenhouses go through a regular process of soil sterilization. This involves pumping thousands of liters of boiling hot water through the soil and is dangerous, time consuming and costly, with the system for sterilization alone costing over ¥3 million. Sterilization also occurs only up to 15cm, leaving deeper soil untouched.

The Radiant System offers a simpler solution, a short process carried out every summer. A clear plastic tarp is laid on the floor of the greenhouse and the house is closed. Water heated to 80 °C is circulated through the underground pipes 24 hours a day for 6-14 days due to weather conditions. Boiling the soil, microbes, pests and their eggs are killed up to 80cm below the surface. Costs for the Radiant System reach ¥1.7 million per 1000m², with operational costs tens of thousands of yen less than the traditional sterilization method, not including the additional benefits of reduced water consumption.

Going green

Although initial costs have made some agriculturalists reluctant to make the investment, the Radiant System’s boiler is easy to maintain and replace and the pipes have long-term durability. With support from local governments, farmers have been gradually waking up to the system’s benefits.

With some selling at nearly US$2000 a pair, mango production is big business

With some selling at nearly US$2000 a pair, mango production is big business

New legislature has also paved the way for the adoption of the system. In December of 2006 the Law on Promotion of Organic Agriculture was enacted, and a series of guidelines was drafted for the systematic promotion of organic farming. The Miyazaki Prefectural government approached Radiant System’s founder Takeo Sugiura, asking if his technology could assist in energy reduction, therefore lightening the burden of organic production on farmers. Sugiura translated reports documenting the success of similar systems in the United States and presented the information to Miyazaki representatives. Impressed, they tested the system on mangoes, a prefectural fruit of which 50% of production costs are absorbed by fuel. The results were surprising: not only was the system extremely energy efficient, but it also produced a 30% increase in yield.

A radiant future

Fuel prices are sky rocketing, and it’s time we moved past that into a more sustainable electric-based system

As effective as the Radiant System is, Sugiura feels a need to push forward and evolve. “Fuel prices are sky rocketing, and it’s time we moved past that into a more sustainable electric-based system.” The next stage of development for ground heating systems, he says, is the replacement of fuel-powered boilers with the air source heat pump.

Unlike a boiler, which burns fuel to heat water, an electric air source heat pump uses the refrigeration process to compress low temperature energy into high temperature energy, then transfers this heat to water. While most heat pumps use excessive energy to compress cool air into heat, Sugiura realized that a vast pocket of naturally heated air is already available inside greenhouses during the day, just waiting to be utilized. Due to the inherent design of a greenhouse, the air inside often becomes too hot, even during winter or in colder climates. This excess solar-generated heat is released outside, and from Sugiura’s point of view, wasted. Radiant’s heat pump technology harnesses this warm air to assist in heating the circulated water to a desired 40°C.

It’s a simple principle, but highly effective in reducing the amount of energy required to run the system. Greenhouses could become almost completely self-sufficient, requiring only an electrical outlet and feeding off of heat that is created in the house naturally. Furthermore, because heat pumps run on electricity, fuel costs are completely eliminated, as are CO2 emissions. Research has shown that the COP (Coefficient Of Performance) of heat pumps is 4-5, compared to 0.6-0.9 for a fuel-powered boiler. All this adds up to a clean and eco-friendly system that works in almost any climate, is low-cost and low-maintenance.

The system is excellent news for farmers moving to organic production but a godsend for the Ministry of Agriculture, Forests and Fisheries which aims to reduce CO2 emissions by at least 170,000 tons by 2010. For every 1000m² greenhouse, optimally calibrated ground heating systems can reduce production of C02 by 8.5 tons per year. Sugiura calculates that, “If only 10% of the current 220,000 greenhouses that fall into this category used Radiant Systems, the Ministry would have no problem meeting its goal.”

Getting the right minerals into the body, and getting them there naturally through food, that’s the key for creating a healthier society both in Japan and worldwide

Sugiura is in the process of patenting the heat pump system in Japan, and has high hopes for the future. But while he is confident the system will succeed, governmental constraints have led him to seek out likeminded individuals to form a partnership both in Japan and abroad. He is openly searching for investment and interested parties from overseas to expand distribution. “This is an essential technology for both drastic energy reductions in agricultural practices and for organic farming. Getting the right minerals into the body, and getting them there naturally through food, that’s the key for creating a healthier society both in Japan and worldwide.” JI

Takeo Sugiura: Radiant Systems Founder

Takeo Sugiura: Radiant Systems Founder

Although he was born in the northern prefecture of Aomori, Takeo Sugiura had little interest in agriculture throughout most of his life. After schooling in architecture he found himself working for Mitsui & Co Ltd with a hankering for the challenge of life abroad. “I wasn’t interested in going places everyone had already been,” boasts Sugiura, and when offered he jumped at the opportunity to oversee the opening of a new branch of the company in Bahrain. This started his eight-year service abroad in Thailand, Bahrain and Pakistan, an experience that taught him resourcefulness but did not quench his thirst for adventure.

When Sugiura finally returned to his homeland, he was ready for the next chapter, and on January 20 1993, at the age of 53, he started his own company under the name of Radiant Corporation Ltd. When asked why he’d chosen that date, Sugiura beamed while citing the inauguration date of one of his idols, Bill Clinton. “At that time, Bill Clinton was America’s proponent for change, and that was a perfect time for me to change my life as well.”

He continues that, “I believe ‘Change is Chance,’ and even as I get older I’m always changing and still plan to change.” While most men his age have been enjoying retirement for almost a decade, Sugiura’s vitality is proof of the minerals he preaches about: pocketing a recent photo of himself at a three-hour aerobics competition inside his wallet, he enjoys Sudoku but finds the puzzles available in Japan too easy. “I enjoy games where you must use your head.”

Comments

SUSHANT DAS (not verified)

March 9, 2009 - 21:53

Permalink

GREEN HOUSE PROJECTS AND CULTIVATION

we are from india Intersted in low cost Green house projects and plantations.Yours site is very informative, please suggest a related sites.