A Western Fit

With size differences proving difficult for men of a Western stature to find a perfectly fitting suit, Isetan Men’s have filled the gap in the market with made-to-order suit tailored to accommodate any fit.

By Kevin Mcgue

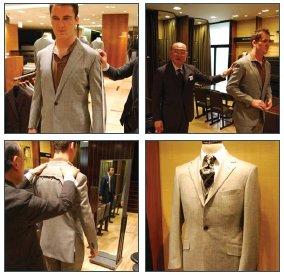

It can be hard for a man of any size or stature to find a properly fitting suit. For those who are big or tall in Japan and find themselves behind a language barrier, this difficult task can seem nearly impossible. For instance, a little-known but vital element of a well fitting suit is referred to in the trade as the “drop,” which is calculated by subtracting the waist measurement in centimeters from the chest measurement and dividing that number by two. A correct drop size allows for free movement of the arms while not being baggy around the midriff. The average drop size in Japan is around 10, and most shops rarely stock jackets with a drop of over 20. Will (see photographs) has a drop size of 24, meaning it would be nearly impossible for him to find a proper fit without going the made-to-order route.

Ordering made-to-order suits can seem like a bewildering task. Fortunately, Japanese retailers have realized this gap in the market and the highly capable staff at Isetan Men’s in Shinjuku can provide expert assistance in selecting a suit that not only fits but also matches one’s personal style.

'The custom order suit department on the fourth floor offers expertise and services in the manner of Savile Row, but in a modern and convenient setting."

Shinjuku Isetan was founded in 1933, and the men’s annex opened its doors in 1968, providing a shopping sanctuary for men. A major remodeling last year brought a heightened sense of luxury with arrival of the world’s first Tiffany & Co boutique dealing exclusively in jewelry for men, as well as a men’s day spa. The new floor plan organizes apparel not strictly by brand, but rather by occasion, with golf gear and sportswear together in one section, and weekend leisure items such as art books and cameras in another. The custom order suit department on the fourth floor offers expertise and services in the manner of Savile Row, but in a modern and convenient setting. Here, some of the world’s finest textiles, linings, and details such as buttons have been brought together in a single location, making ordering a suit both fun and easy. The staff are knowledgeable and helpful, and customers who have a membership in Isetan’s “I Club” can request an English-speaking interpreter to help them with their shopping.

When purchasing a made-to-order suit, there are so many options that it can be difficult to know where to start. A style can be selected from display models at the store, or choosing the fabric can be the point of departure. With over 400 types of fabrics available on bolts, and an additional 1,000 in sample books, this can seem like a formidable task. However, the fabric samples have been collected into books that are grouped not by country of origin or thread count, but rather by style, making it easier to select a fabric for the occasion, be it summer or winter, formal or business. Seeing a sample of the fabric and feeling it with the fingers can give a sense of its sheen and texture, but it is also important to know the weight of a fabric and the way it will drape from the body. For this reason, customers are invited to open up a bolt of fabric and drape it over their shoulders, giving a close approximation of what it will feel like to wear the finished suit.

One fabric that is said to be popular this year is English flannel, an old classic which is making a comeback. Isetan has commissioned a special line of traditional flannel from Fox Brothers in Somerset, England, which has a long and celebrated history. When Churchill was famously photographed in 1940 with a machine gun, cigar and Homburg hat, it was Fox Brothers pinstripe flannel he was wearing. Years later, when Robert Redford needed a white suit to recreate the opulence of the roaring ’20s as described by F. Scott Fitzgerald in The Great Gatsby, it was white flannel from Fox Brothers that was called for. Isetan also stocks a variety of English wool for the autumn/winter season—fabrics that tend to hold their shape well in Japan. Isetan also stocks a number of wools made with traditional man-operated looms, rather than computer-controlled machines, creating weaves that are not entirely uniform, for a nice textured look.

Once the fabric has been decided on, the next step is selecting the cut. The “English Blade” is an English drape suit in the elegant style of the 1930s, accentuating the torso with a relatively high top button. This model is available as a two-piece or three-piece, and also comes in a “Sportsman” model cut especially for men with muscular chests and arms. The “MI6” model is styled after English suits from the early 1960s, with a lower top button for a longer, narrower lapel and a slim silhouette. Think Cary Grant in North by Northwest or Sean Connery in Dr No. The Diplomatico model is an update on the classic wide-shoulder style created by the tailors of Naples. These models start at ¥66,000, excluding tax, with suits made from luxury fabrics costing up to ¥160,000.

Men in search of a more distinctive style should explore the “Style Gate” series (starting at ¥99,000), with models designed by expert tailors from Savile Row, and Japanese designers with extensive experience in Milan and Rome. Richard Anderson, who became one of the youngest head cutters in the history of Savile Row, contributed a classic English double-breasted suit design. And Spencer Hart, known as the bad boy of English tailoring, offers a narrow lapel suit with a hint of a rebellious touch in its styling.

After deciding on the fabric and cut, the next step is selecting the lining, piping, and buttons. Touches such as genuine horn buttons can add a touch of elegance, while a colorful lining inside an otherwise conservative suit can add a sense of play.

The final step is a fitting. Isetan staff swiftly and skillfully take measurements, and the customer tries on a prototype suit in an approximate size. Fine adjustments are made with pins and clips, and the customer is on his way. The made-to-order suit will be ready in three to four weeks. However, service does not end with the finished product simply being handed over. Customers are welcome to try on the new suit to make certain everything is perfect. Staff can also help by suggesting shirts, neckties, and pocket squares to complete the final look. JI

Comments

Dan (not verified)

February 22, 2009 - 02:22

Permalink

fabric

I have a suit that was made for me and , the pants need to be remade, the shop still has the original bolt , will the pant and the jacket still match