Knotted Beauty

How the Japanese cedar tree found new life

By Simon Shiida

The cedar tree in Japan

World War II caused tremendous environmental damage to Japan, the majority of the country being forested land. During the post-war reforestation projects, Japan was implanted with an influx of Japanese cedar trees, (Cryptomeria Japonica) as they were easy to plant and would grow quickly. During this post-war restoration period and the expansion years afterwards, timber from Japan’s forestlands made up a substantial contribution to Japan’s economic expansion.

Currently, Japan is 67% forest and of that 13% is cedar. So why is it that only 20% of lumber comes from Japan? Japan spends over ¥1 trillion annually on the importing of lumber, mainly from Canada and Finland. This has caused an over-growth of cedar forests in Japan and as a result, an astonishing amount of problems, such as environmental damage in developing countries because of large-scale tree felling for low-cost timber import to Japan, as well as avalanches and landslides in Japan caused by devastation of the forests and damage to streams and torrents.  President Sanzo Okada speaks about the cedar tree’s potentialAnother problem with the over-abundance of the cedar tree is unpopularity from the public because of the severe hay-fever caused from the extreme pollen emitted during spring time.

President Sanzo Okada speaks about the cedar tree’s potentialAnother problem with the over-abundance of the cedar tree is unpopularity from the public because of the severe hay-fever caused from the extreme pollen emitted during spring time.

However, from another angle, the cedar tree is an untapped source of wealth and has a very deep connection with the lifestyle of the Japanese people. In fact, the cedar tree can be traced back to ancient times—an excavation of an ancient site in the Fukui prefecture brought to light a number of canoe-like boats (dating back to c.3500 BC) which were carved out of cedar wood, proving that this ductile timber has been used for centuries. The wood was also commonly used for housing, ships, buckets, wagons and so on. As a result of rapid economic growth, lumber from overseas was imported in large volumes and as Japanese lifestyles began to become more westernized, use of cedar as a building material sharply decreased.

Recently, however, the Japanese cedar tree has found a new life again, and is now being used for furniture.

Hida Takayama and Hida Sangyo

Nestled near the Northern Japan Alps of Gifu prefecture lies Hida Takayama (known as Hida locally), a mountainous area full of lush greenery and natural surroundings. An area steeped in history, most famously, Hida is known to nurture a strong collection of highly skilled wood craftsmen originating back to the 7th Century Nara period. Many of these excellent craftsmen were responsible for constructing the magnificent wooden temples of Kyoto and Nara such as the World Heritage Horyu-ji, which still stands today after 13 centuries. This love of woodwork can be said to come from being one of the greenest areas in Japan—93% of Hida is made up of forest with 20% of that being the cedar tree.

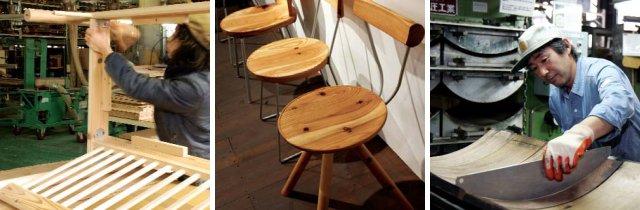

Craftsmen within the Hida region are legendary, with their craft being passed down through the generations for over a thousand years. While these craftsmen are highly traditional, they are also quick to pick up new technologies, which have enabled the quality production of furniture from the region. One local company, Hida Sangyo, pride themselves on their high quality furniture, with 100 of 300 employees owning a first or second level craftsman’s proficiency qualification. Companies like Hida Sangyo draw top quality craftsmen from all over the country to train and improve their skills in wood crafting.

Each piece of furniture is carefully handcrafted, showing attention to detail

Each piece of furniture is carefully handcrafted, showing attention to detail

Words of the wood

When Sanzo Okada entered Hida Sangyo, one of the most historic woodwork furniture manufacturers in Japan, as President in 2000, he had thought that surrounded by such abundant forests, of course the timber used for furniture would be taken locally. He was surprised to find that over 90% of the lumber the company used was imported, often knotted materials that were unappealing in the furniture industry. It all started when Okada asked the question, “What’s wrong with knots?”

He pressed the issue that knots are part of a wood’s natural beauty and by creating furniture with knots in it, each piece is unique. Their first series, ‘Mori no Kotoba’ (words of the woods) had a huge impact and proved that Japanese customers were becoming increasingly appreciative of the way of nature and ecology. At this time, Okada thought, “Why not get them to see the strengths in using cedar?”

Wood compression and bending techniques

Wood compression and bending techniques

Ceder was seen as undesirable because, not only is the knotting very prominent, but the wood is also very ductile and is prone to dent and scratch and is not tough enough to endure the wear-andtear of everyday usage. However, the popularity of the “Mori no Kotoba” series proved that knots were no problem, leaving only the hardness issue. It was at this time that Okada coincidentally came across the wood compression technology. While the technology itself was still in the early stages, Okada realized that this could be used within his company to enhance its wood bending techniques.

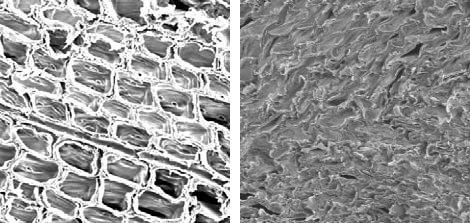

Wood fibres before and after compression

Wood fibres before and after compression

Hida Sangyo, one of the most historic woodwork furniture manufacturers in Japan, adapted an Austrian wood compression technology into the stateof- the-art method it is today, enabling craftsmen to harden the tender wood, a process which involves increasing a woods hydration and heating it up in order to soften it, then bending the wood into shape. Following that, pressure is put on the wood with a press, increasing its density by removing excess space from its cellular structure. This increases the strength and ability to manufacture the wood, as well as preventing it from changing shape in the future. (See figure above)

With the technology they developed, they also realized that by using different shaped presses, uneven surfaces as well as lamination is also possible. This new technology enables furniture to be created at lower costs with a larger variety of possible designs due to the elimination of certain stems in manufacturing.

Their furniture received huge approval from famous Italian designer Enzo Mari, who taught Okada to see the beauty of Japanese designs and to stop emulating European furniture, a style which had proved the most popular in Japan. Okada agreed but was keen that Mari should start making furniture with Hida cedar. Initially, Mari was reluctant, concerned that he might be damaging the local environment. However, the company went to Italy to explain to him that Japanese cedar, unlike other types of forest, re-grow on a 50-year cycle and it would therefore be no problem to use such trees for lumber.

The Hida series is popular with celebrities in New York as well as Tokyo

The Hida series is popular with celebrities in New York as well as Tokyo

It was from this meeting that the ‘HIDA’ series was borne, with 20 pieces that display the beauty of the knotted cedar wood. The collection was a huge hit in Milan and became a hot topic amongst designers and architects, seen to be a concept where Japan meets Italy. This furniture is created by gathering and combining Japanese technology with the Italian power of design, creating contemporary work where nostalgia and novelty connect. The collaborative collection was presented at the Triennale, a sanctuary of industry design in Milan, in April 2005 and won the 2007 ‘Craftsmanship award’ at the International Contemporary Furniture Fair in New York.

Fans include a famous clothes designer who bought a whole selection of the luxury furniture as well as some commissioned pieces for the Japanese Imperial Palace and the distinguished Keio University. Okada says there is more to the pieces than meets the eye: “Not only is the design exceptional but all our furniture is designed to insure that above all else, it is really comfortable to use.” One example are the Hida chairs. Each seat has a calculated concave and the backrests are angled at the perfect position to provide the utmost comfort as well as the striking appearance. The products are only lightly varnished which enhances both the natural beauty of the wood as well as leaving it soft and smooth to the touch.

Since its foundation in 1920, Hida Sangyo has grown from 6 to 300 staff, providing employment and economic support for the local area. Carrying forward what they have achieved in Japan, the company is now looking to expand abroad. Their next step is to source retail agents in Western countries such as Europe and America, taking the Hida brand to a global level.

The Hida people are proud of what the area has achieved and what it has to offer. As Okada says: “I want people to be able to experience the natural beauty of the trees through our furniture.”

Enzo Mari – Designer

Enzo Mari

Enzo Mari

One of the most thoughtful and intellectually provocative Italian designers of the late 20th century, Enzo Mari has a design history spanning over 50 years.

Born in Novara, Italy in 1932, he studied classics and literature at university whilst also working as a visual artist and researcher. In 1952, he opened a design studio in Milan and since then, has worked with Danese, Muji and most recently, Hida Sangyo.

The depth and complexity of Mari’s work ensures that he is greatly admired by the design community and, in his seventies, is still a very sought after designer.

The Hida collection can be found at their Omotesando store

HIDA OMOTESANDO

Omotesando Hills B2F

4-12-10 Jingumae

Shibuyaku

Tokyo 150-0001

Open: everyday

Monday-Saturday 11:00-21:00

Sunday 11:00-20:00

Tel: +81-3-5785-1200

Fax: +81-3-5785-1295

Email: omotesando@em-hida.jp

Web: www.em-hida.jp