|

Minato's Magnetic Motor is quite different from the four fundamental types of motors manufactured today. The most modern designs, be they AC or DC, servo or stepper, all fundamentally employ the same principle of electromagnetic force of attraction that was first discovered almost 200 years ago. Their designs all suffer significant losses in efficiency caused by the coils, the core, and consequent magnetic losses (eddy currents). These losses are typically given up as heat from the system. Minato's Magnetic Motor is quite different from the four fundamental types of motors manufactured today. The most modern designs, be they AC or DC, servo or stepper, all fundamentally employ the same principle of electromagnetic force of attraction that was first discovered almost 200 years ago. Their designs all suffer significant losses in efficiency caused by the coils, the core, and consequent magnetic losses (eddy currents). These losses are typically given up as heat from the system.

Minato's magnetic motor uses magnetic repulsion as its core source of energy and suffers very few losses. It creates almost no heat, and is substantially more efficient (up to 330 percent) than conventional motors.

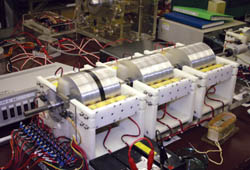

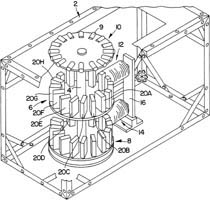

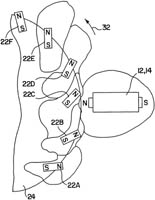

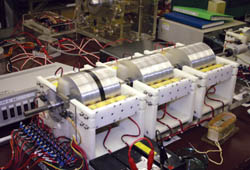

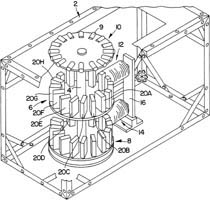

Most of Minato's test units consist of a three-layered, non-magnetic rotor fitted with powerful Sumitomo Neomax (neodymium-iron-boron) magnets located (for a duration of 5 degrees) every 175 degrees around the circumference of the rotor. The magnets possess a powerful force of 5,000 gauss and repulsively interact with the two diametrically opposed fixed electromagnetic stators. The rotor moves due to the stator electromagnets bouncing the rotor magnets away from the stators -- in the direction to which the rotor magnets are inclined. The stator electromagnets are pulsed at specific intervals and durations (about 10ms at start-up, and reducing in period to 2ms as the rotor reaches its natural speed), to make sure that they are only energized when facing a departing rotor magnet. Most of Minato's test units consist of a three-layered, non-magnetic rotor fitted with powerful Sumitomo Neomax (neodymium-iron-boron) magnets located (for a duration of 5 degrees) every 175 degrees around the circumference of the rotor. The magnets possess a powerful force of 5,000 gauss and repulsively interact with the two diametrically opposed fixed electromagnetic stators. The rotor moves due to the stator electromagnets bouncing the rotor magnets away from the stators -- in the direction to which the rotor magnets are inclined. The stator electromagnets are pulsed at specific intervals and durations (about 10ms at start-up, and reducing in period to 2ms as the rotor reaches its natural speed), to make sure that they are only energized when facing a departing rotor magnet.

Minato overcame a number of obstacles that have stopped other inventors from realizing a magnetic motor earlier (although there have been a lot of attempts). The first is that the rotor magnets use repulsion and not attraction to reduce the amount of energy needed. Second, the positioning and angle of the magnets on the rotor are critical to providing the right "glancing" motion of rotor and stator fields, bouncing off each other to create repulsive (and thus motive) force. Also, the magnets have to be powerful, something that only became possible after neodymium magnets appeared in the 80s.

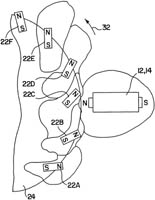

The north-south structure of any magnet can be maintained by making the rotor with three layers: a top layer with the north pole of the neomax magnets facing outwards, a non-magnetic layer, and a south pole outward-facing layer. These layers are aligned with the opposing north-south poles of the two electromagnets. The pulse timing on the electromagnets is the key to creating a "sweet spot" for the repulsion between rotor and stator. Timing is created by means of sensors picking up timing marks just before the rotor magnets appear. The north-south structure of any magnet can be maintained by making the rotor with three layers: a top layer with the north pole of the neomax magnets facing outwards, a non-magnetic layer, and a south pole outward-facing layer. These layers are aligned with the opposing north-south poles of the two electromagnets. The pulse timing on the electromagnets is the key to creating a "sweet spot" for the repulsion between rotor and stator. Timing is created by means of sensors picking up timing marks just before the rotor magnets appear.

The rotor is started and stopped by applying and removing energy to the two stator electromagnets. After a deceleration period, the rotor aligns with the magnets facing the iron cores of the stator electromagnets.

@

|

Minato's Magnetic Motor is quite different from the four fundamental types of motors manufactured today. The most modern designs, be they AC or DC, servo or stepper, all fundamentally employ the same principle of electromagnetic force of attraction that was first discovered almost 200 years ago. Their designs all suffer significant losses in efficiency caused by the coils, the core, and consequent magnetic losses (eddy currents). These losses are typically given up as heat from the system.

Minato's Magnetic Motor is quite different from the four fundamental types of motors manufactured today. The most modern designs, be they AC or DC, servo or stepper, all fundamentally employ the same principle of electromagnetic force of attraction that was first discovered almost 200 years ago. Their designs all suffer significant losses in efficiency caused by the coils, the core, and consequent magnetic losses (eddy currents). These losses are typically given up as heat from the system.

Most of Minato's test units consist of a three-layered, non-magnetic rotor fitted with powerful Sumitomo Neomax (neodymium-iron-boron) magnets located (for a duration of 5 degrees) every 175 degrees around the circumference of the rotor. The magnets possess a powerful force of 5,000 gauss and repulsively interact with the two diametrically opposed fixed electromagnetic stators. The rotor moves due to the stator electromagnets bouncing the rotor magnets away from the stators -- in the direction to which the rotor magnets are inclined. The stator electromagnets are pulsed at specific intervals and durations (about 10ms at start-up, and reducing in period to 2ms as the rotor reaches its natural speed), to make sure that they are only energized when facing a departing rotor magnet.

Most of Minato's test units consist of a three-layered, non-magnetic rotor fitted with powerful Sumitomo Neomax (neodymium-iron-boron) magnets located (for a duration of 5 degrees) every 175 degrees around the circumference of the rotor. The magnets possess a powerful force of 5,000 gauss and repulsively interact with the two diametrically opposed fixed electromagnetic stators. The rotor moves due to the stator electromagnets bouncing the rotor magnets away from the stators -- in the direction to which the rotor magnets are inclined. The stator electromagnets are pulsed at specific intervals and durations (about 10ms at start-up, and reducing in period to 2ms as the rotor reaches its natural speed), to make sure that they are only energized when facing a departing rotor magnet.

The north-south structure of any magnet can be maintained by making the rotor with three layers: a top layer with the north pole of the neomax magnets facing outwards, a non-magnetic layer, and a south pole outward-facing layer. These layers are aligned with the opposing north-south poles of the two electromagnets. The pulse timing on the electromagnets is the key to creating a "sweet spot" for the repulsion between rotor and stator. Timing is created by means of sensors picking up timing marks just before the rotor magnets appear.

The north-south structure of any magnet can be maintained by making the rotor with three layers: a top layer with the north pole of the neomax magnets facing outwards, a non-magnetic layer, and a south pole outward-facing layer. These layers are aligned with the opposing north-south poles of the two electromagnets. The pulse timing on the electromagnets is the key to creating a "sweet spot" for the repulsion between rotor and stator. Timing is created by means of sensors picking up timing marks just before the rotor magnets appear.